Issue

Older equipment utilized high pressure natural gas from the compressor discharge lines for pneumatically actuated unloading devices. The high pressure gas allowed the actuator piston size to be relative small. Since the actuation gas was equal to or less than the process gas the devices were sealing against in the closed position. The lower the actuation gas pressure the larger required diameter of the actuator piston.

To open the unloading device the pneumatic pressure must be vented to allow the pressure in the cylinder body to move the unloading device to the open position. Most devices are vented to atmosphere or require a flare stack. Due to modern emission standards the use of natural gas as a pneumatic media causes concern.

Tubing and shaft seal leaks with natural gas are also a safety concern.

ACI Expert Advice

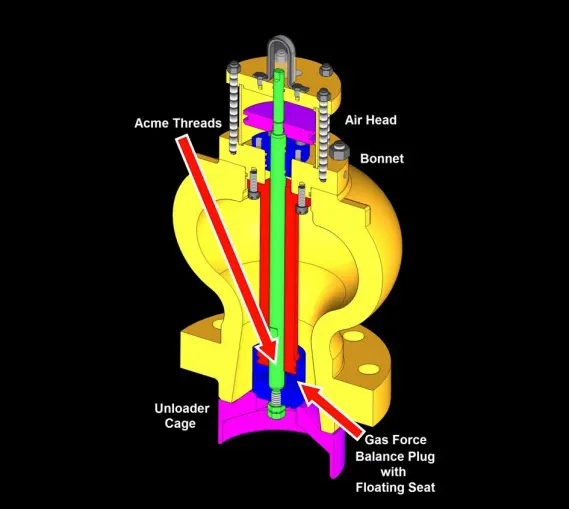

ACI Services can replace existing natural gas pneumatic actuators, or manufacture complete replacement unloaders, with small diameter pistons to a balance plug piston design to function using 90-130 psig pneumatic air pressure from an off the shelf air compressor. The balance plug design allows relatively small diameter pistons to seal unloading devices against pressure as high as 3,000 – 4,000 psig.

Because the pneumatic media is compressed air, the emissions and safety concerns from leakage are mitigated.