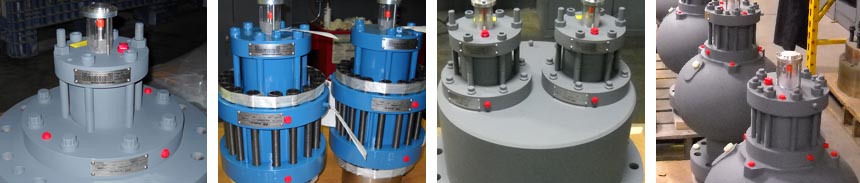

Unloading Devices

ACI offers a line of volume and bypass Unloading Devices. ACI also supplies a range of actuators for reduced volume demands, variable operating pressures, and reduced discharge pressures.

Reciprocating compressors are the most efficient gas compressors available when they are operating under the optimum conditions for which they are originally designed. They rarely run at optimum conditions. In fact, without some sort of capacity control device, they would often be operating well below optimum efficiency or overloaded to a point where they would have to be shut down.

As a result, many compressors are supplied with manually operated variable volume clearance pockets (VVCPs) which are often not repositioned while the compressor is operating due to the severe device oscillations which occur when the device is unlocked. The AutoPocket performs these adjustments automatically while the compressor is operating without the station personnel needing to manually unlock the device, reposition it then relock it, eliminating the need to subject the station personnel to the oscillating handles while repositioning the device.