Acoustics

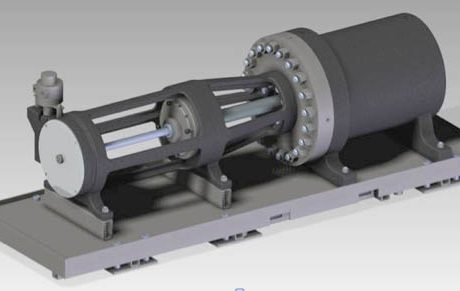

ACI designs and manufactures acoustic attenuation and pulsation control devices that can solve vibration issues while often reducing pressure losses.

API Standard 618 Fourth Edition, June 1995, design approach options 1, 2 or 3. Includes evaluation of pulsation suppression devices and supports considering static loading, acoustical shaking forces and mechanical responses.

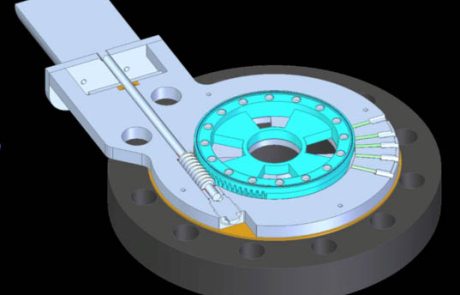

To introduce the Tunable Side Branch Absorber to Market, the Southern Gas Association Gas Machinery Research Council (GMRC) and ACI Services Inc. (ACI) have completed a license agreement that authorizes ACI to develop and market products that incorporate GMRC’s patented tunable side branch absorber (TSBA) technology.