eRCM Pro™ features:

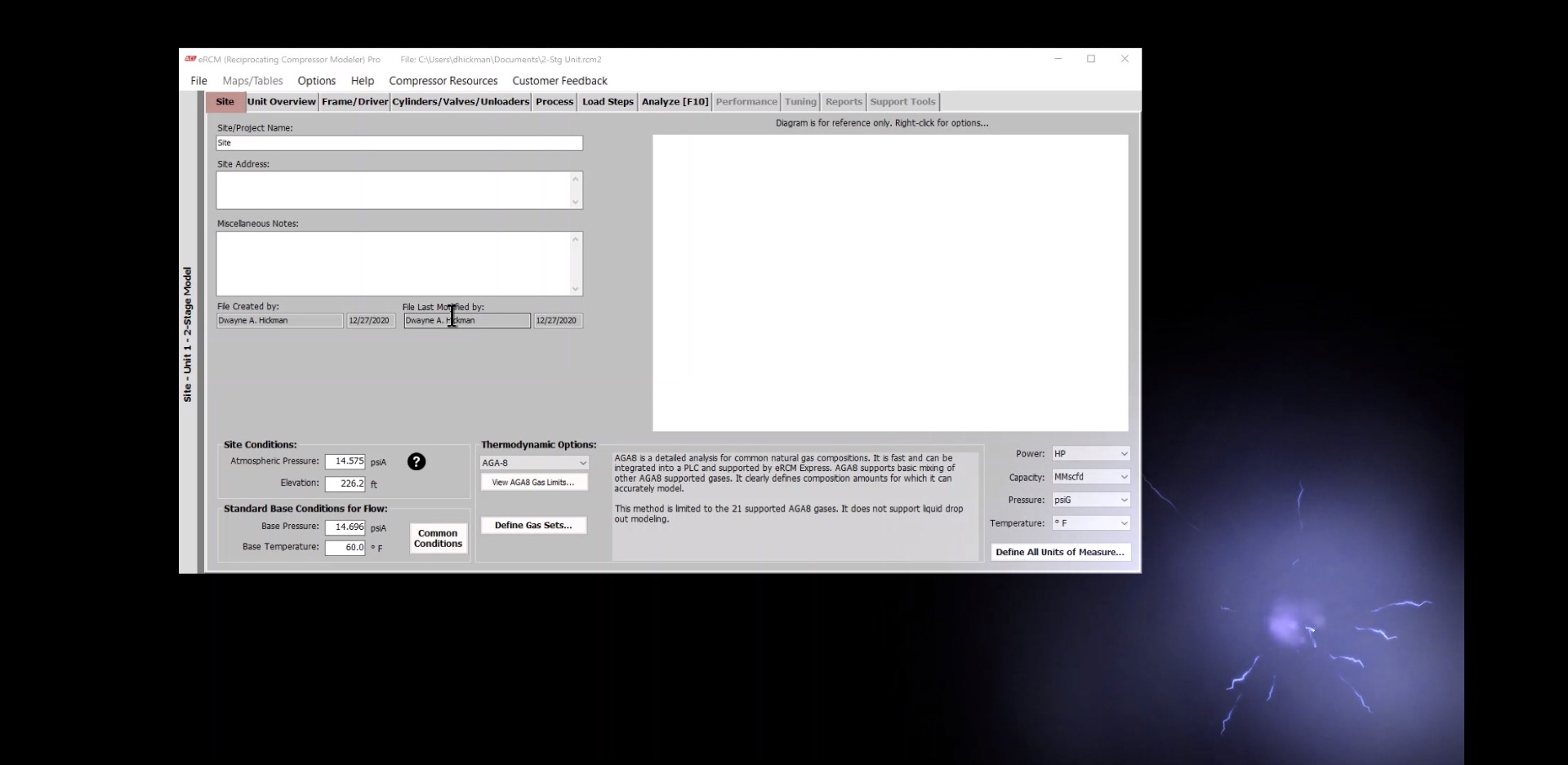

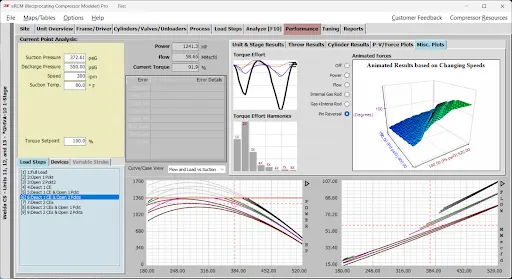

Users specify compressor geometry (frame, cylinder, stage, throw, valving, etc.), operating ranges, gas analyses, and unloading devices. eRCM Pro then calculates and displays unit performance outputs such as powers, flows, pressures, and temperatures.

While unit performance is very important, safety is even more critical. eRCM Pro software models unit safety according to how the OEM of that equipment expects it to be modeled. Since OEM calculation methods and limits vary between OEMs, your specific equipment needs to be modeled according to its manufacturer’s safety requirements.

eRCM Pro also helps end users decide on hardware changes. Over time, typical operating pressures may change at a station. Within seconds, a user can model adding a new fixed-volume clearance pocket to a cylinder to identify if that proposed change provides sufficient unloading to accommodate the new operating pressures.

No compressor performance program is complete without an ability to improve its predictions. eRCM Pro accepts results from analyzer data and then uses this real-world data to tune performance predictions to better accommodate the effects of pulsation, pressure drops, effective clearances, actual valve and parasitic losses, friction losses, and more.

eRCM™ Downloads

| Title | ||

|---|---|---|

|

eRCM™ Evaluator The features of this software have been implemented directly within eRCM Pro. 1 file(s) 26560 downloads |

eRCM, eRCM Legacy Software | Download |

|

eRCM™ Legacy This software has been replaced by eRCM Pro™ Software. Please upgrade. 1 file(s) 26460 downloads |

eRCM, eRCM Legacy Software | Download |

|

eRCM™ Points Report The features of this software have been implemented directly within eRCM Pro. 1 file(s) 22955 downloads |

eRCM, eRCM Legacy Software | Download |

Click the video to view Dwayne Hickman’s initial training video introducing ACI’s eRCM Pro™ software, and key features and sections. Ideal for those already familiar with eRCM™.

Click the video to view Dwayne Hickman’s initial training video introducing ACI’s eRCM Pro™ software, and key features and sections. Ideal for those already familiar with eRCM™.