Issue

High HP compressors can cause mechanical stress, which leads to metal fatigue and failure if not addressed.

ACI Expert Advice

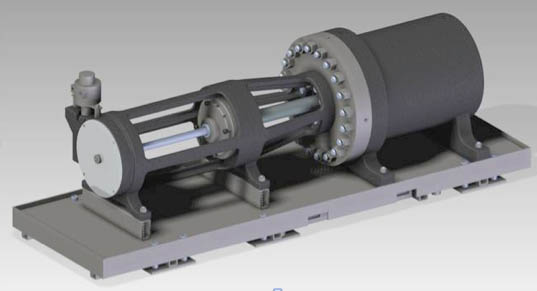

Due to the design of reciprocating compressors, where a piston is moved back and forth inside a cylinder, waves of gas are compressed and are discharged. These waves are often described as pulses. In the early days of the natural gas industry, the horsepower of the compressors was low enough that the pulsations would not cause any ill effects to the piping of the unit.

Due to the design of reciprocating compressors, where a piston is moved back and forth inside a cylinder, waves of gas are compressed and are discharged. These waves are often described as pulses. In the early days of the natural gas industry, the horsepower of the compressors was low enough that the pulsations would not cause any ill effects to the piping of the unit.

Today’s higher HP compressors are another matter. The wave action on a modern-day compressor produces wave action high enough to cause mechanical stress that can lead to metal fatigue and failure if not addressed properly.

If you are experiencing visible vibrations in the piping, flanges, supports, etc. near your units, this should trigger an investigation into the type of pulsation problems (i.e. frequencies) and the magnitude of these pulses.

To do this, an Acoustic Study is often the first step in determining the nature of your pulsations. The study uses unit information and piping lengths and diameters along with the location of supports to determine the system-wide pulsations and predict where vibrations (mechanical and acoustic) may be present. These studies will provide recommended actions to take to mitigate the pulses. These actions are usually in the form of installing additional support straps and installing pulsation mitigation products to help to reduce the pulsation or mechanical vibration to a manageable level. These products take the form of Orifice plates, Side Branch Absorbers and even new Pulsation Bottle configurations.

ACI offers a host of services and products to help mitigate pulsation and keep your unit running safely.

Our services include:

Our services include:

- Acoustic Studies that model your unit to determine the extent of pulsation

- Piping and Pulsation Bottle design and manufacture

We also have unique products for pulsation mitigation that are state-of-the-art and are unique to the industry including:

- Tunable Side Branch Absorbers (tSBA)

- Dynamic Variable Orifice Plates

For more information, visit our Acoustics page.