Reciprocating Compressor Experts

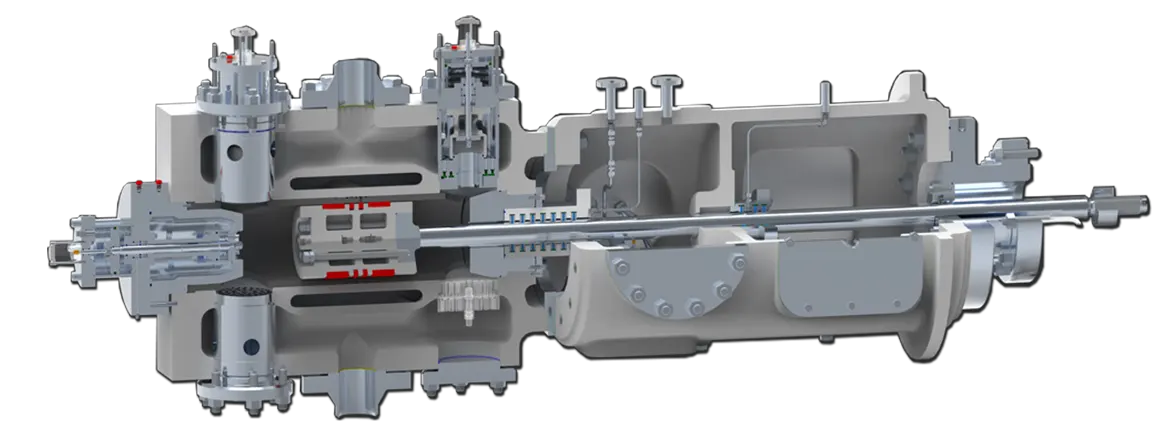

ACI Service, Inc. is the industry leader in providing engineered solutions for reciprocating compressors. ACI’s customer-centric solutions are built upon ACI’s advanced performance modeling abilities, detailed manufacturing of innovative hardware products, effective customer service, and developing and comparing multiple solutions to identify the best option for each customer to meet their goals and objectives.

Find Your Solution

Type below to search for common issues. Chances are, we have a solution.

Cylinder Cracking

Zero-Hour Maintenance

Capacity Control

Valve Failure

Parts Request

Automate Manual Devices

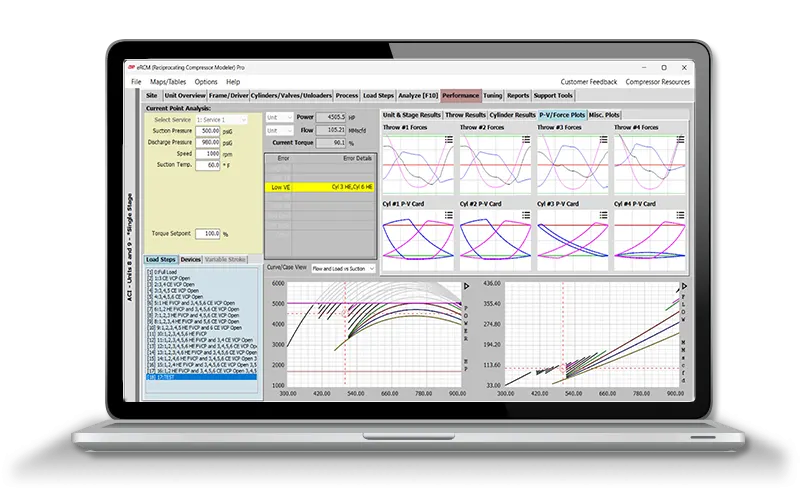

ACI’s eRCM Pro™ Modeling Software provides the ideal solution to model compressor performance.

eRCM Pro™ displays the unit’s performance curves:

- Models compressor performance and safety according to OEM methods.

- Interactive and fast!

- International aware with full complement of units of measure.

and more!

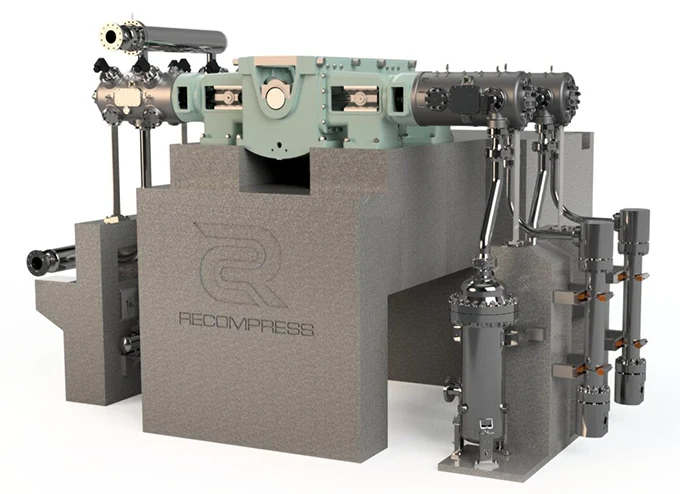

eRCM Express™ is an industrial computer that powers reciprocating compressor modeling technology. Remove operating map constraints from your reciprocating compressor. Allow it to achieve its full performance.

- Predicts safe performance across unit’s full operating map

- Calculates full rod loads and pin reversals

- Simple, just connect the power and Ethernet

- Provides OEM-compatible modeling

and more!

Training from the Experts

eRCM Thermo Overview™

On-DemandNeed a quick overview of ACI’s eRCM™ Thermo Software? Then this is the video for you.

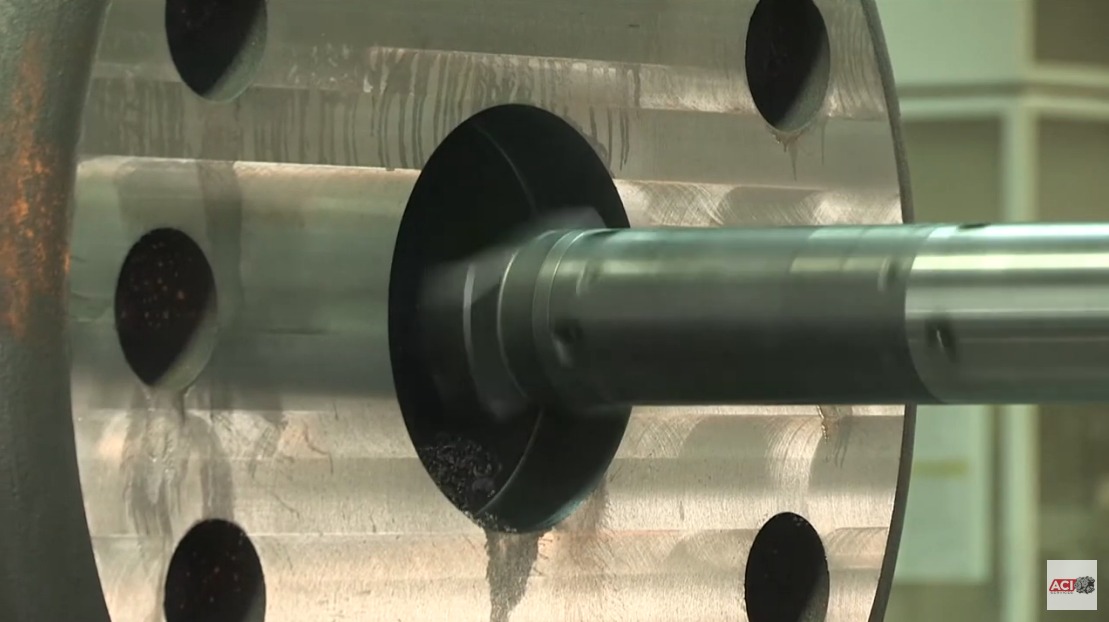

Boring a Cylinder

On-DemandBoring a large block of metal that can weigh multiple tons is challenging. Making sure tolerances are met, smoothness of finishing is met, and porosity is not encountered are additional challenges. This video helps clarify the machining process.

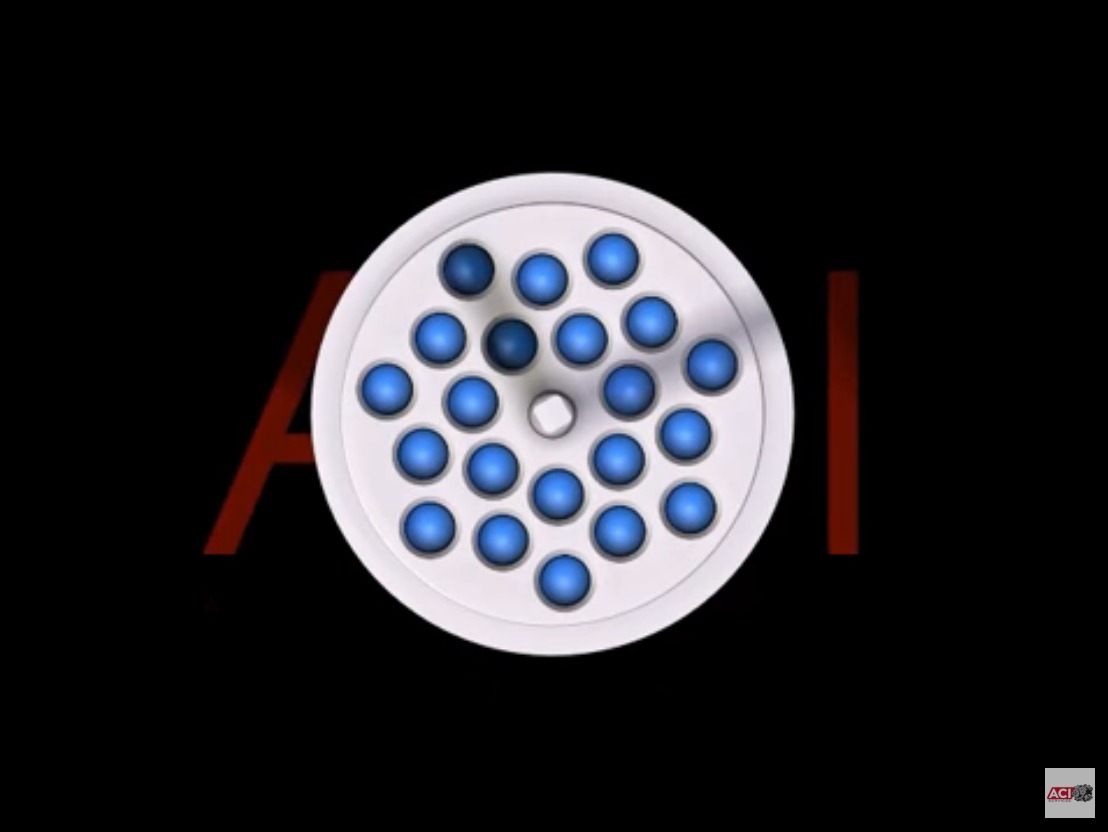

Rotavator Valve Unloader

On-DemandRotavators are useful to deactivate cylinder ends when poppet valves are used. This animation shows how rotavator valves work, and how they can be used to unload compressors.

Success Stories

SITUATION:

The existing compressors, (4) Worthington BDCcompressors, no longer supported by the OEM. Old pipeline plant moth-balled for many years. Purchased by Spire Storage with limited reciprocating compressor experience.

CUSTOMER’S NEED:

ACI’S SOLUTION:

-Darren Morris